What will you learn from this article?

- What is the main goal of performance models?

- What does it mean that performance models are tail-specific?

- How can tail-specific performance models lower airlines’ costs?

A tail-specific performance model is an innovation, which becomes more and more popular in the aviation industry. Probably you are wondering what exactly performance models are, and what does it mean that they are tail specific?

Link to the AircraftIT publication

The main goal of a performance model is to calculate the fuel consumption over time at defined conditions. For example, if you would like to know the flight time, distance, and fuel burn of descent – you need a performance model. If you put into the model an aircraft weight, speed, and weather forecast, you will get information about how your descent profile will look like. Because such a model “knows” how much you will burn for every possible condition, it can tell the speed that will give the lowest fuel burn or cost.

So why are there so many rumors about tail-specific models? In a nutshell, each aircraft is different from the others: some have higher drag, other engines are a bit less efficient and some are modified beyond the legacy performance model. All of these have an impact on fuel burn. If you put all aircraft of the same type into one model you lose what makes each aircraft individual. With tail-specific performance models, you get the highest precision of fuel consumption calculation. While FMS or Flight Planning Software usually has one – a legacy model for all aircraft of a given type, nowadays it is possible to get a separate model for each tail number, each engine & APU.

While legacy models were mostly used for calculating approximate in-flight fuel consumption, by using machine learning and big data from QAR/FDR the new generation of tail-specific performance models can answer many more questions:

-

- What is the true difference in fuel consumption between single and dual engine taxi, taking into account uphills, downhills, engine aging, and APU model?

- flaps and acceleration altitude for any airport?

- What is the accuracy of flight planning’s fuel policy calculations?

- Does the low setting of air conditioning packs induce fuel saving?

With machine-learning models, StorkJet can compare how much fuel an airline would burn in the exact same weather and operational conditions if the pilot would make different decisions (like using different flaps, performing SE taxi, flying with different speeds or altitudes, or descending earlier).

Such an approach allows to assess the importance of every aspect of fuel policy and aircraft performance, and easily find ways to improve and cut costs by giving more vital information to fuel efficiency departments, performance engineers, policymakers, and pilots.

Let’s check real cases of how tail-specific performance models can lower airlines’ costs.

Individual degradation factors delivered ASAP

In the traditional Aircraft Performance Monitoring process (APM) the degradation factors are jumping from month to month even by 1%. As a result, airlines need to average the results over one or three months. Meaning that when there is a large change in aircraft performance (eg. engine change to a more efficient one by 2%), the airline will fly even for 3 months, planning 2% more fuel than needed. In the opposite situation, when degradation would increase by 2%, pilots can notice overburns and as a result, start to plan higher discretionary fuel. Both situations result in a fuel penalty.

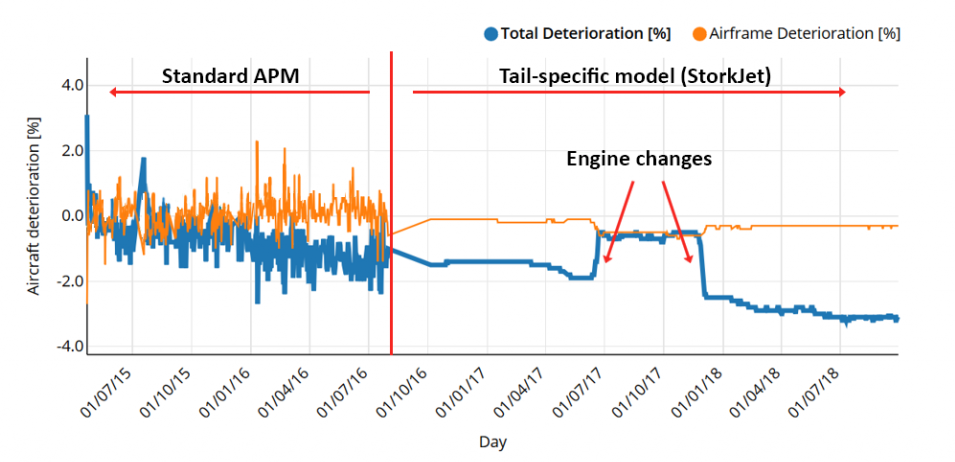

With tail-specific performance models, airlines can very precisely determine the performance of an aircraft at any specific point in time. In the chart below, you can see that after an airline switched from traditional APM to StorkJet’s AdvancedAPM, aircraft deterioration calculations look much smoother. Also, there were two engine changes, with more than a 2% change of Total Deterioration visible on the first flight after the maintenance action. Thanks to that, airlines can change the fuel factor on their flight plan just after the change occurs, and as a result, save fuel.

Optimum speeds and altitudes designed for each tail

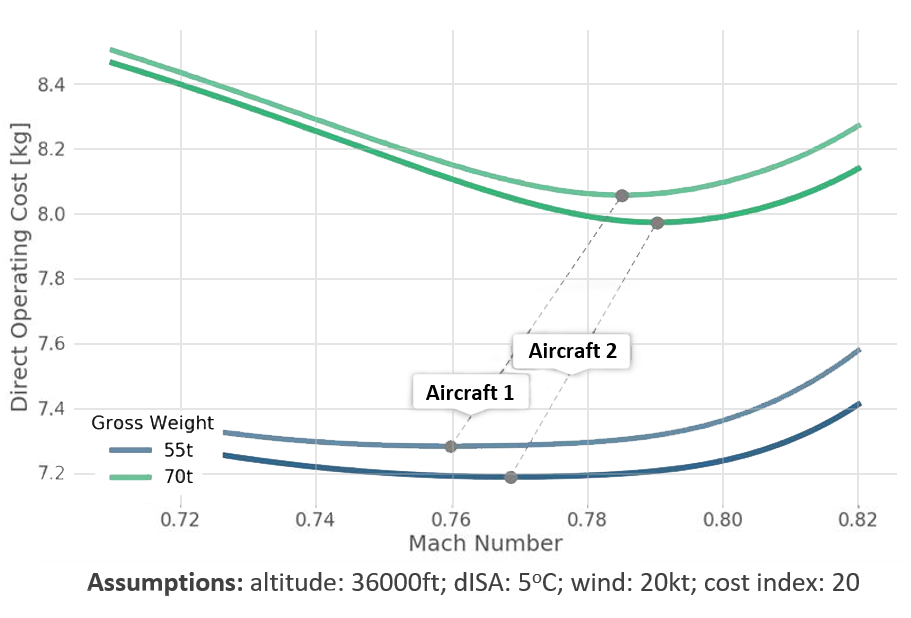

Another case where individual aircraft characteristics matter is Flight Profile Optimization. Let’s analyze real data from two aircraft of the same type. For the same gross weight, route, and weather conditions both flight plan and FMS would give the same ECON speeds and altitudes for them.

On the chart below you can see what is the actual Direct Operation Cost (fuel burn + cost of time) for these aircraft. As you can see from the gray points and dashed lines, the economical speed on cruise differs by up to 0.01 Mach between both aircraft. It appears that these two aircraft of the same type, are in fact, very different.

When having a deeper look at how much can be saved by this difference, the saving potential of AC-2 is 20% larger than the saving potential of AC-1. By using tail-specific performance models airlines can see a such difference and advise pilots to fly differently (in this case a bit faster) on AC-2 to be aware of all of the possible savings. This can be done by scheduling AC-2 flights with a bit higher cost index.

Detailed feedback to pilots

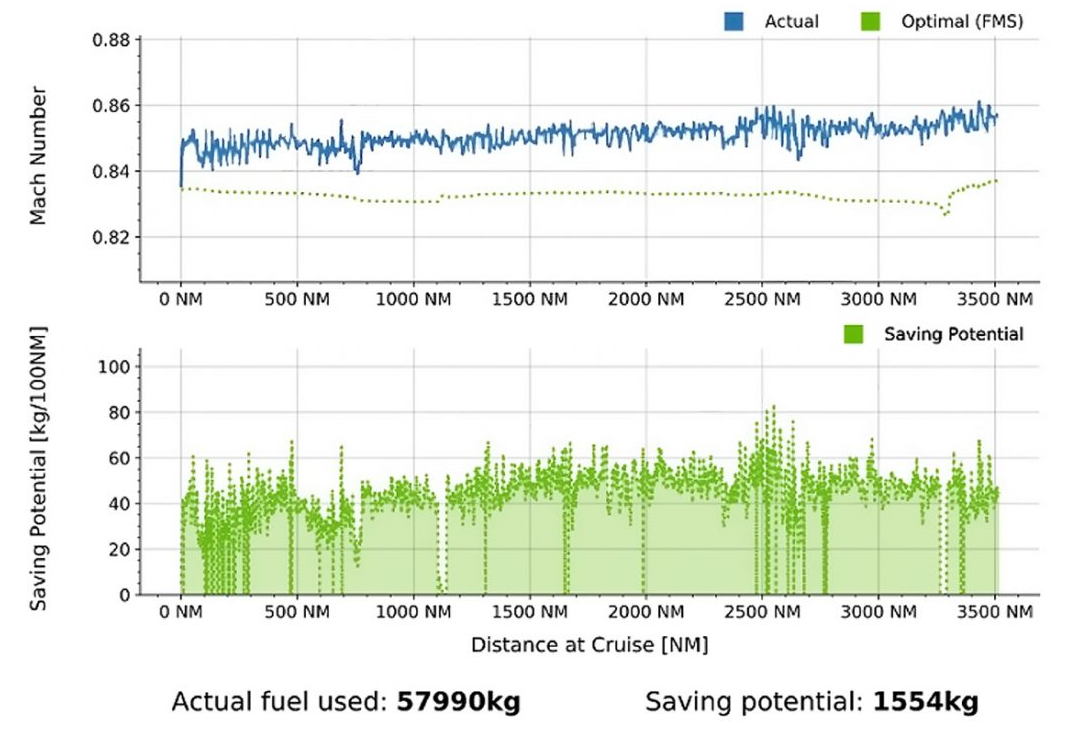

As we all know, pilots are the key players in fuel efficiency. They also need to understand what impact their behavior has on fuel consumption. At StorkJet, pilots receive after each flight comparison of their flight path to the most optimum one. These charts optimize flight speed and vertical profile during a climb, cruise, and descent.

Below, an example of the cruise speed optimization chart is presented. The optimum speed is marked as the green line and the actual one (blue line) is the one selected by the pilot. The green area is the saving potential, which in that flight is equal to 1554 kg. With such information, pilots can check where the areas for improvement are and what actions might have the biggest impact on CO2 reduction.

True savings from Single Engine Taxi

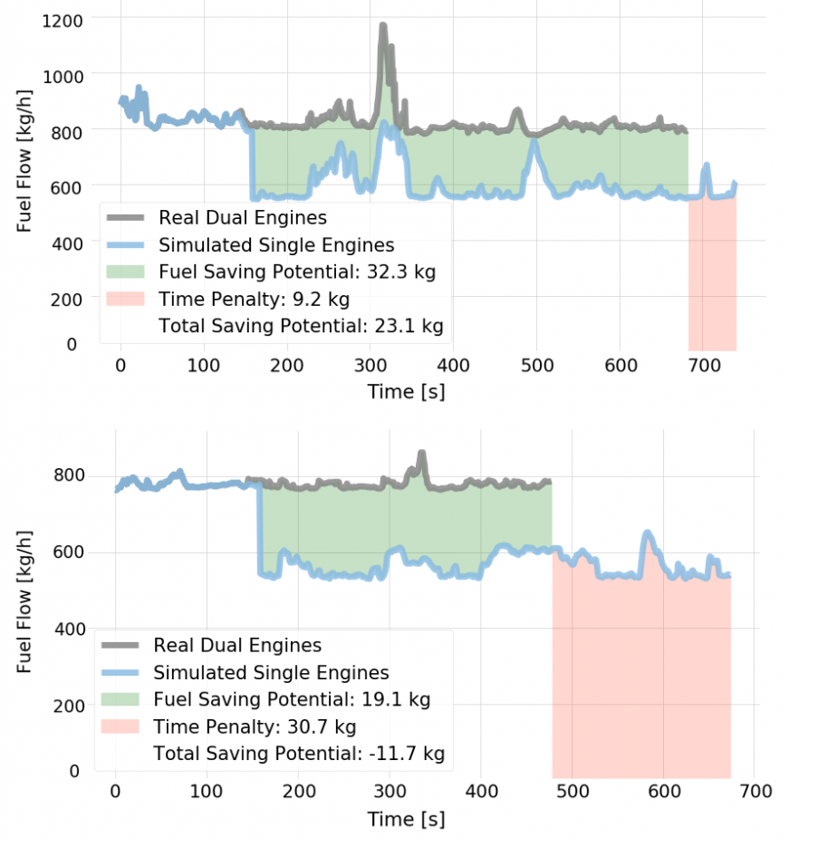

There is common knowledge on the market that when taxiing with a single engine, the airline will save for example 5 kg per one minute of taxiing on medium-range aircraft (after a cooling period). This might lead to wrong conclusions because taxiing on a single engine takes longer than a dual one, which generates a fuel penalty.

Some airports might have uphills, so single engine will be even slower. Or on the contrary, there might be traffic in some airports – in that case, single-engine generates more savings because we wait in a queue only on one engine.

By creating dedicated models for a taxi, StorkJet takes into calculation all the above-mentioned relations. When a pilot performs a dual engine (grey line), he might compare it to the single one, which is fully simulated (the blue one).

On the charts, we can see what is fuel saving potential (green area) as well as the time penalty (red area). The above chart shows an example of when a pilot in total saved 23 kg of fuel. The example below shows a case when the single-engine would generate a fuel penalty equal to 11,7 kg. On the contrary, in the standard approach, both cases would show the same fuel savings.

Thanks to apple-to-apple comparison calculated for each flight and each fuel initiative, analysts can easily find these areas of operations where the biggest savings are hidden.