What will you learn from this article?

- What is the goal of Aircraft Performance Monitoring?

- What are the most popular actions that affect Aircraft Performance Monitoring?

The goal of Aircraft Performance Monitoring (APM) is to know the up-to-date performance of each aircraft in the fleet to plan and execute flights in an optimum way and as a result, reduce fuel burn. This is done by measuring the actual fuel consumption of each aircraft and comparing it to the fuel consumption of a new aircraft. The difference, which is called the Performance Factor or Degradation Factor, is later used in multiple systems, including FMS and Flight Planning System. Precise Performance Factors are crucial for accurate fuel planning, tail assignment, safe reduction of contingency fuel as well as speed and altitude optimization.

To allow you to achieve maximum savings, we have prepared the 5 most popular errors that airlines make while setting up the APM process together with recommendations on how to solve these issues!

Performance factors update frequency

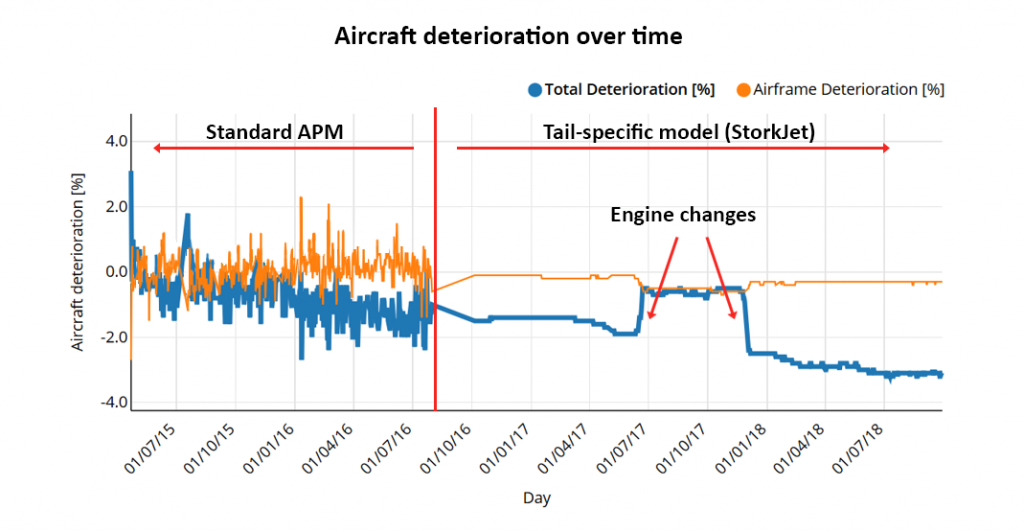

Technical events and engine replacement often result in a significant change in performance factors overnight. This corresponds to a few hundred kilos of planned block fuel, which depending on the situation, would be just a few hundred kilos of unnecessary weight or a few hundred kilos of overburning, undermining the crews’ confidence in fuel planning, which leads to the captain taking extra fuel.

What we observe on the market is that airlines update performance factors once a month, three months, or in the worst-case scenario, they use assumed values (eg after 5 years the degradation should be -4%). Of course, the more often we update performance factors, the better. The recommended option would certainly be once a month. However, with StorkJet’s AdvancedAPM you can update performance factors even daily. In case of an engine change, a new performance factor will be updated & made precise just after a single flight.

Rounding of performance factors

The high scatter of legacy APM is often addressed by smoothing or rounding Performance Factors to the nearest integer. Similarly, updating frequency also negatively affects the planning of the block fuel.

To achieve higher precision and to stay conservative, instead of rounding to the higher integer, the airline can use the average performance factor plus standard deviation. With StorkJet’s APM, the spread of data is much lower, allowing the use of precision Performance Factor with a resolution of 0.1% right after one day of flying after an event like a bird strike or engine change.

Fuel flow calibration

All popular APM systems are based on fuel flow meters. Their precision is key to the APM. Typically, mass fuel flow meters are very precise and differences between Fuel on Board and fuel flow calculations are negligible. There are, however, aircraft types and tail numbers that suffer from fuel flow meter issues reaching imprecision as high as 8%. During the flight, pilots can compare the amount of fuel burned (based on fuel flow meter reading) with the change in gross weight of the aircraft, and report any differences to performance engineers, so the airline can calculate what is the imprecision.

Using AdvancedAPM this process can be fully automatized. If differences are detected the software calibrates Fuel Flowmeters measurements using Fuel on Board data, to ensure accurate Performance Factors.

Gross weight errors (Aerodynamic)

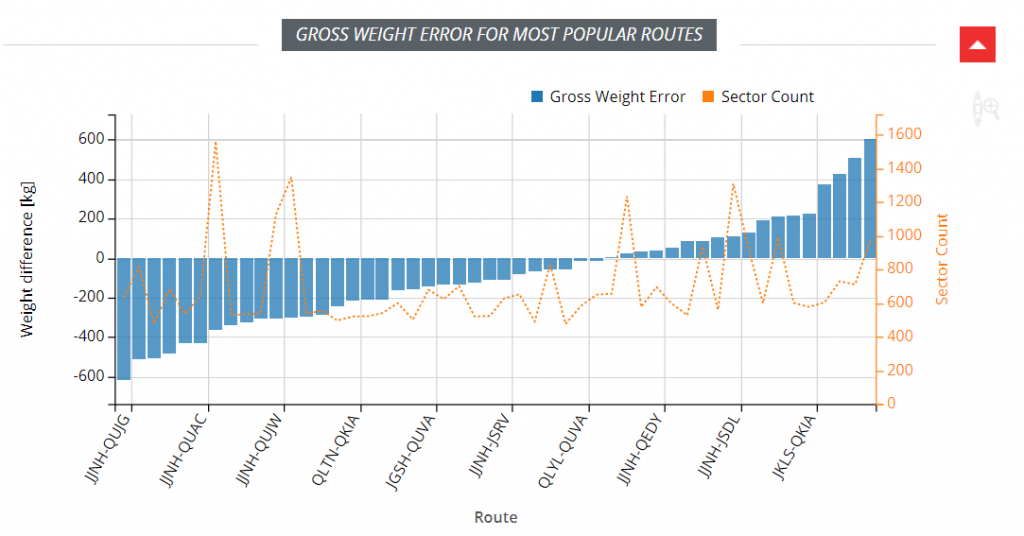

Errors in assumed passenger weights are the single biggest factor contributing to APM imprecision. It can differ because of city pairs or seasonality (passengers are heavier during winter and lighter during summer). Identification of city pairs where these errors are the highest enables taking steps and adjusting weights to the proper ones. Realizing what is the actual, true weight of the passengers is difficult.

In AdvancedAPM genuine algorithms utilize QAR data and Machinery Learning to calculate gross weight errors for each city pair over time.

Mixing Performance Factors with long term CDLs impacting aircraft performance

Aircraft’s Configuration Deviation List allows operations with missing external parts, which often penalizes fuel consumption – this is indicated by drag increment or percentage of extra fuel burn. Sometimes it can take weeks or months before CDLs are rectified. In this case, the mixing of CDLs and APM Performance Factors will cause the application of the doubled penalty, where the Performance Factor can be adjusted to accommodate the penalty incurred by CDL and reduce the penalty to a realistic minimum.