As we know, any amount of unnecessarily tanked fuel makes the aircraft weigh higher and thus the aircraft burns more fuel during the flight.

For this reason, one of the most important aspects, when it comes to fuel efficiency, is to use the right amount of fuel for your flight – to keep the highest level of both safety and efficiency at the same time.

How can airlines do this with sophisticated AI-powered software?

Check out the article below released by Aerospace Tech REVIEW where our VP Piotr Niedziela explains the outstanding possibilities of StorkJet software.

Link to the full Aerospace Tech REVIEW article

eMISSIONS: Taking Control of Reducing Emissions and Saving Money

Aviation has come a long way in reducing its emissions, with new generation engines and aerodynamic tweaks such as winglets producing significant savings.

However, the next stage is harder, with only smaller incremental changes possible. One technology being applied is big data.

Aircraft generate massive amounts of data and advances in processing have allowed the development of innovative solutions that can help to save fuel. One hindrance to these is crowded airspace, which means altitude changes for more favorable winds, shortcuts by direct routing, or continuous descent approaches are not always possible but it is still possible to make other aspects of a flight more efficient. In addition, burning fuel to carry fuel can be reduced by more accurate planning.

StorkJet, based in Katowice in Poland, helps airlines save fuel with advanced data analysis. Thanks to artificial intelligence they monitor precisely aircraft performance and optimize fuel consumption across 44 fuel initiatives. Its customer base includes JetSMART and Volaris in South America and Air Atlanta, LOT Polish Airlines, and Wizz Air in Europe. Air Astana signed up in July 2021.

Piotr Niedziela, co-founder and head of Business Development, explains that one of the company’s products is AdvancedAPM which helps airlines precisely monitor aircraft performance and diagnose root causes of performance degradation. It compares the actual fuel consumption of each aircraft to a brand-new one. The difference is called the performance factor and is later on used in multiple systems like FMS and Flight Planning System to properly plan fuel for the flight, as well as optimize speeds, altitudes, and trajectory of the flight.

The second StorkJet product is FuelPro — a fuel efficiency platform with over 44 options across the entire spectrum of airline operations that can be optimized, including fuel policy, flight planning, ground operations, APUs, departure, flight speed, vertical profile optimization, and arrival. Each fuel initiative has a dedicated AI mode, that creates ‘what if scenarios’, compares fuel burn between them, and indicate the precise savings potential that an airline can achieve. Such powerful analysis can be further broken down into time periods, airports, runways, aircraft types, individual aircraft, and many more.

As pilots are the most important factor in the efficiency process, with FuelPro they also have a dedicated app where they can check their fuel score. They are being encouraged in a friendly way and being informed how much CO2 or trees they have saved with efficient flights. After each flight, they receive a debriefing with information on how close they were to optimum policies, like optimal flight speed and vertical profile during the climb, cruise, and descent.

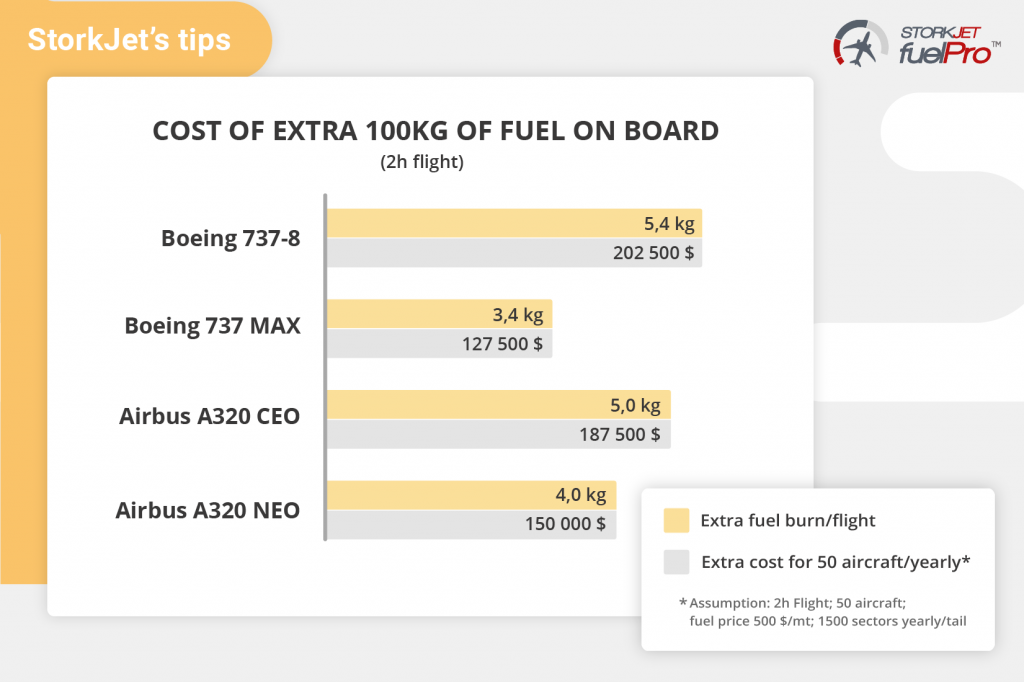

One example of where fuel savings can be made is the amount of additional fuel that is carried. There are many different types of additional fuel that could be safely optimized like contingency fuel, final reserve, discretionary, alternate fuel, etc. Looking at the numbers, even with 100kg fuel less onboard an airline operating 50 aircraft can save between $120,000-200,000 annually (see Figure 1.)

In the case of LOT Polish Airlines, it used FuelPro to reduce Contingency Fuel on their Boeing 787 fleet. The result was a change in policy from 5% to 3%, which brought savings of $1.8 million in just one year.

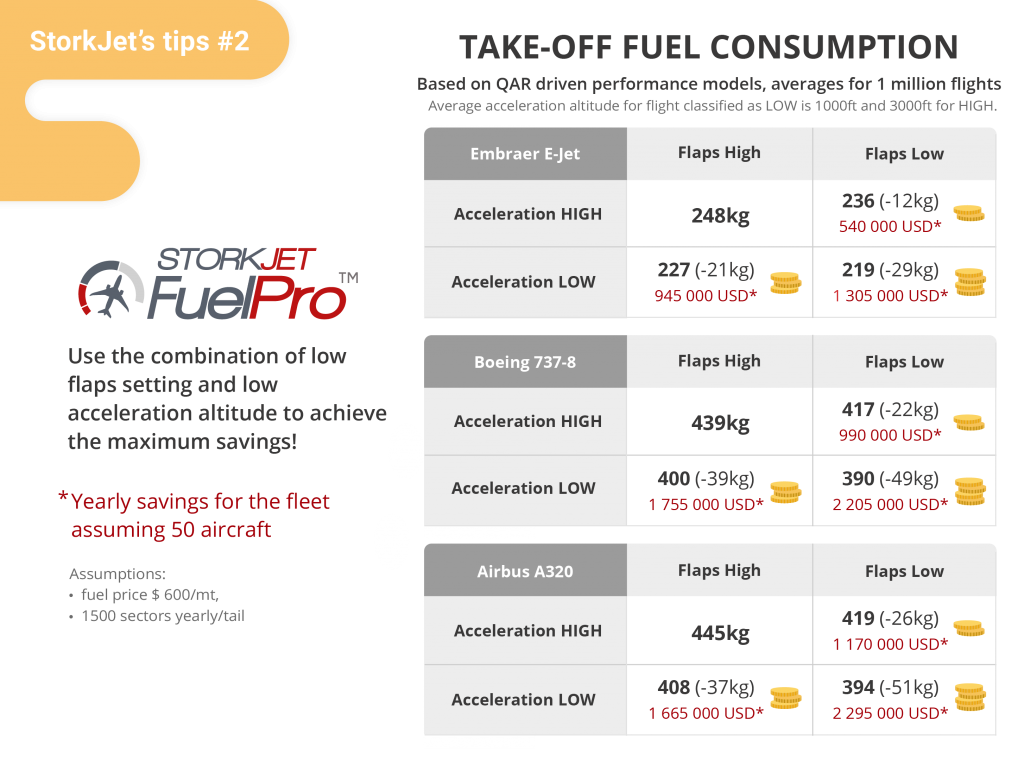

With FuelPro airlines can also easily check what is the real saving potential by using low acceleration altitude and low flaps during take-off. What might be interesting is that with AI models airlines can check different scenarios and be aware of the real impact of non-compliant flights. Averages, based on 1 minute of flights are shown in Figure 2.

At the moment the company is working on an EU-funded project for real-time optimizations — fuel briefing and debriefing via the EFB.