The flag carrier of Poland, LOT Polish Airlines, shares their challenges in setting up a modern fuel efficiency program – From the general idea and setting goals, to gaining experience from StorkJet’s FuelPro implementation and use.

Article is published in AircraftIt magazine

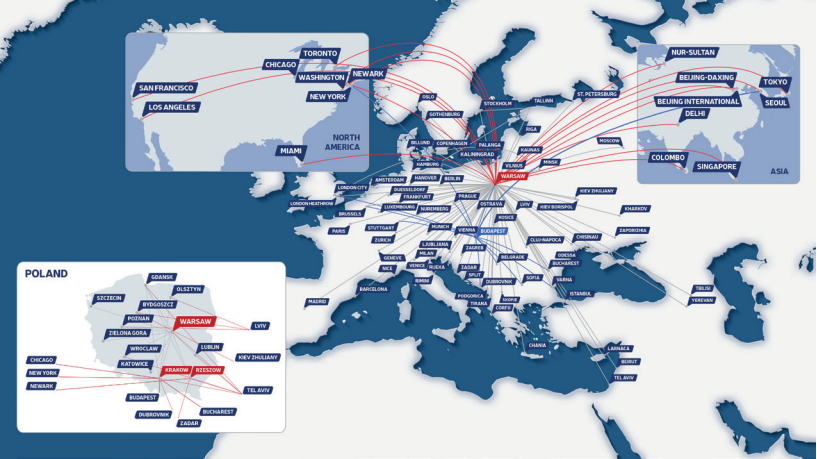

The heart of this article is the implementation of a new fuel efficiency software system in LOT Polish Airlines. But first some background about the airline’s history, fleet, and flight network. LOT Polish Airlines combines tradition with modernity. Being one of the twelve longest-established airlines in the world, LOT has been connecting Poland, Central, and Eastern Europe with the world for more than ninety-one years (Figure 1).

Lot at Glance

Every year, LOT hosts millions of travelers on its aircraft, carrying over 10 million passengers in 2019. The crane is a bird that is a symbol of strength and stability and it has been part of LOT’s logo for ninety years. Cranes are noted as long-distance flyers but LOT does not only fly long-haul (figure 2).

The airline’s flight network has been structured to answer the needs of modern-day passengers. LOT connects Central and Eastern Europe with the main destinations in the region, Western Europe, and the most important business centers in Asia and North America, operating domestic, short-haul, and long-haul flights which have guided the composition of the fleet.

Network

There are almost ninety aircraft in the LOT fleet (Figure 3) from eleven different airframe and engine combinations, including jets and turboprops, from three aircraft manufacturers: Embraer, Boeing, and Bombardier. In terms of the age of the fleet, LOT is one of the youngest and most modern in Europe.

One of the youngest fleets in Europe

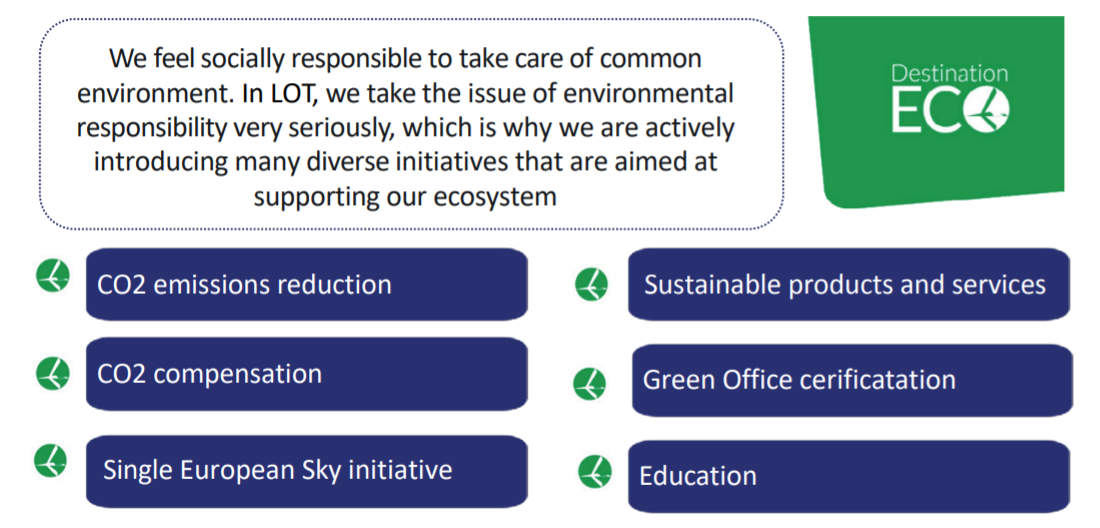

As a company, LOT is well aware of its responsibility to take care of the environment and takes that responsibility very seriously. Operating more sustainably is LOT’s long-term goal and one of the greatest opportunities to reduce aviation’s CO2 footprint. Beyond the modernization of the fleet, that environmental responsibility is met through implementing more efficient procedures – both onboard and on the ground – everything to make operations greener.

Destination ECO

The Destination Eco program (Figure 4) is closely related to fuel efficiency and CO2 reduction.

Challenges in fuel efficiency

Moving on to fuel efficiency, let’s take a look at the key challenges concerning LOT’s fuel program. In 2017, LOT started the implementation of a fuel efficiency policy in the company. At the start of the project, several initiatives based on best practices were established: things already known to the industry as fuel savers. The potential savings were only estimated and it was very difficult to say whether the actions that had been takentaken were actually workingd fleet grew, LOT started to face increasing difficulties maintaining already recognized initiatives. Not to mention the implementation of new ones.

Due to the variety of manufacturers, aircraft types, and models represented in the fleet as well as different data sources, data collection became a challenge for LOT. Most of the time was spent generating data instead of analyzing it. Also, aircraft avionics software is not free from errors which led to the point where LOT wasn’t able to cover all of its fleet. Another challenge was communication with pilots who are considered to be the key players in LOT’s fuel efficiency program. Without their cooperation, it would be impossible to have a successful fuel program. By focusing only on generating data, LOT was unable to identify where the potential fuel savings might be found, which rendered the implementation of further fuel initiatives pointless.

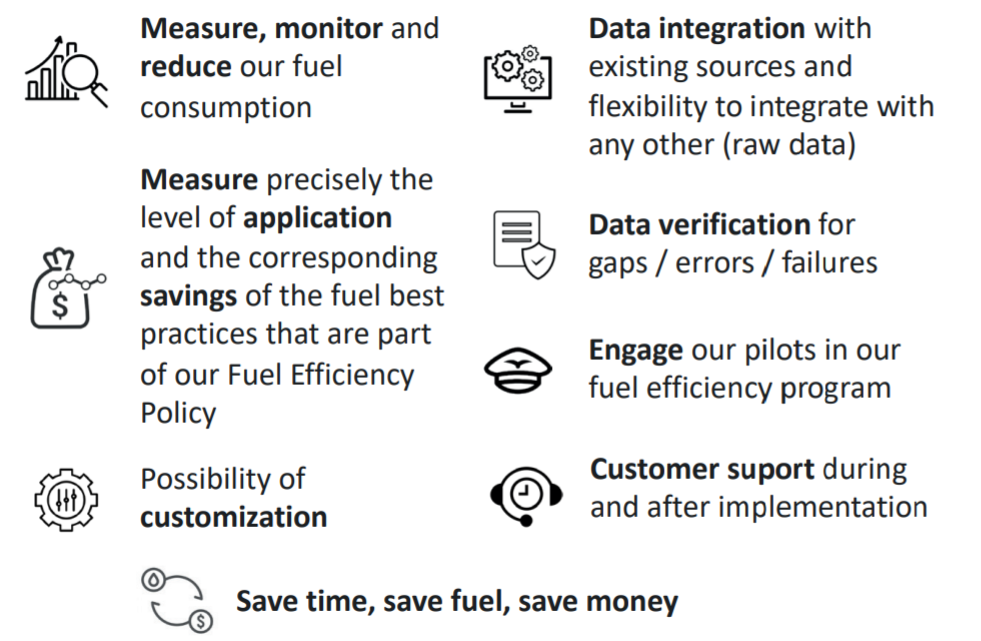

People felt helpless to move things forward. However, being aware of the imperfections in the existing solution, LOT decided to look for software that would allow them to move the center of gravity from data collection to data analysis. In short, a game changer.

The goals

To find the best solution, with which the airline could move forward, LOT OUR established what would be their needs (Figure 5).

The airline needed to monitor its already recognized fuel efficiency initiatives with the possibility of creating self-developed analyses and also define targets, goals, and KPIs for compliance monitoring of each initiative. We have already discussed challenges around data so, clearly, data integration and verification were a top priority. Engaging pilots in the fuel efficiency program was also high on the list: LOT wanted to give them a window on their results versus others as well as showing where and how improvements might be achieved.

The solution

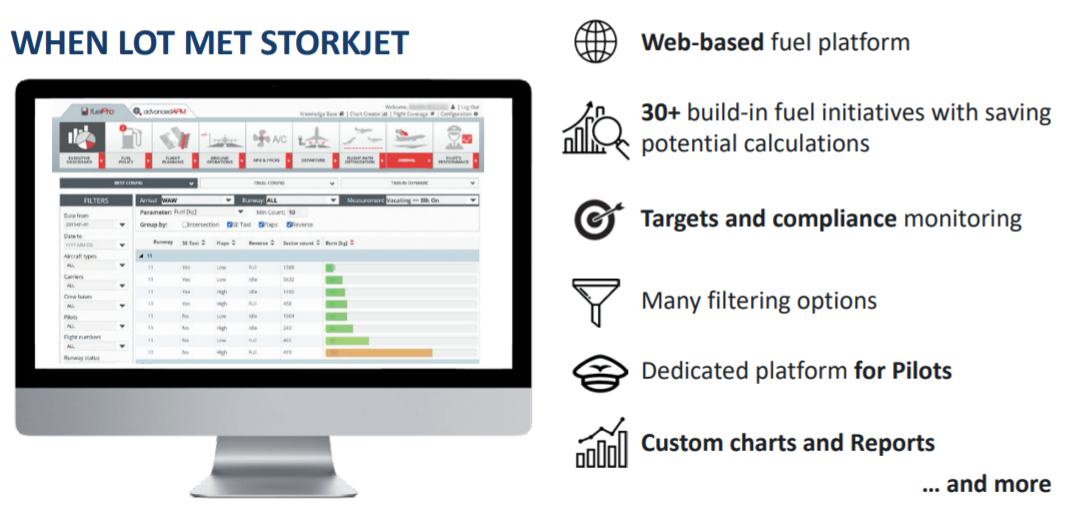

Many readers can probably relate to all that is written above. But at the end of the day, everybody wants a solution that will let them analyze, implement and improve fuel efficiency initiatives which would lead to actual savings. Although everybody might seem to want the same, if we look deeper, individual needs might be slightly different. That’s why LOT was looking for a solution that would offer the possibility of customization. LOT didn’t just want to buy a box with some already-developed features with no room for changes. For LOT, all of those needs and even more were answered when we met the StorkJet team (Figure 6).

As a result of that meeting, in 2019 LOT started the implementation of fuelPro, a web-based fuel platform that helps to analyze and track cost savings and fuel initiatives at all flight stages. Now, LOT manages more than thirty fuel initiatives, easily finding potential savings. The solution allows them to review any fuel statistics and set targets for each initiative as well as check whether they are fulfilled by the crews and dispatch. All of the data provided in the software is of great value for LOT’s procedures and company policies.

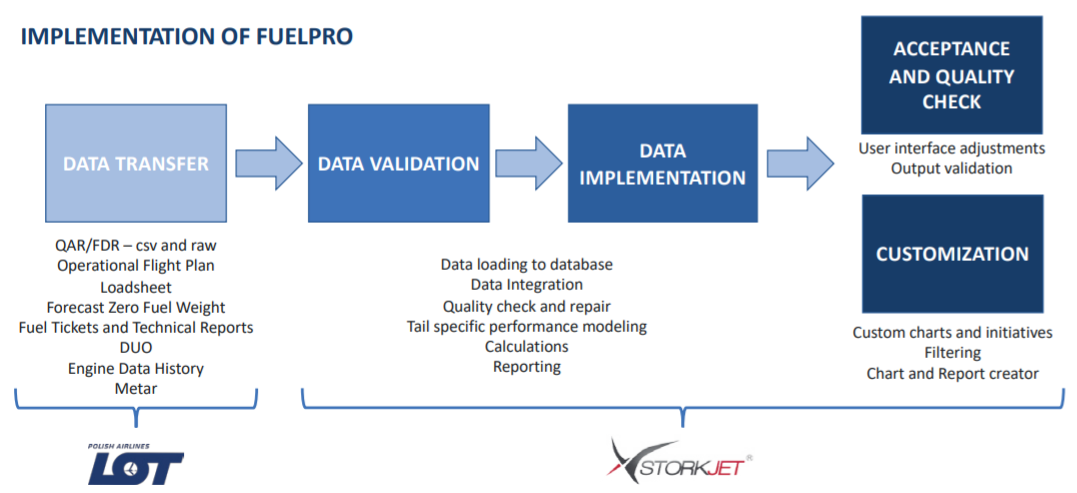

Implementation of FuelPro

Let us now take a look at how the implementation of fuelPro went at LOT. In one word, it could be described as simple for LOT as their only job was to provide source data of proper quality while the rest of the implementation was carried out by StorkJet. LOT provided quite a few data sources (figure 7) although, in all honesty, some of those were far from perfect.

Another issue was that, with the diversity of the fleet, LOT had very different needs for every initiative. Considering the imperfection of the data, StorkJet had to perform a set of quality checks, necessary repairs, and the exclusion of outliers before matching all data sources to produce one version of information about every single flight. For each flight, a set of performance indicators were calculated for every fuel efficiency initiative. The ultimate goal was to achieve the highest data quality possible in one application. StorkJet definitely met that goal.

StorkJet made the acceptance environment ready during the implementation, which made it possible to see how new data appeared in real time. At the same time, there was the opportunity to comment on the user interface and submit proposals for changes. One important thing to mention is that the fuelPro environment is fully customizable: StorkJet made many individual changes to the platform to suit LOT’s fleet, operations, and network, starting with filtering and validation options to adding extra charts and totally new initiatives plus the possibility to create custom charts and reports. The best part is that from the time of signing the contract to a fully customized one, the productive solution was only five and a half months. For LOT, fuelPro is the solution that will grow and develop with the airline; a solution that adapts to their values, needs, and expectations.fuelPro is also a team of great specialists who are ready to support LOT at any time.

Analytical Tabs

Now, let’s look at how LOT uses fuelPro towards actual savings that have already been achieved. fuelPro is mainly used daily by LOT’s fuel team to measure, track and monitor the progress of fuel initiatives, to stay on track and, to make adjustments when needed. Because fuel is one of the main costs for an airline, fuelPro is a great tool for LOT’s management board. From the dedicated executive dashboard, they can track fuel goals and check actual savings.

Fuel efficiency is not only of interest to the fuel department; it also concerns other departments throughout the company. The platform is also used by the airline’s chief pilots, fuel efficiency pilots, weight and balance, and flight planning departments to help them identify areas for improvement and monitor the application of best practices. One of the most important groups is the pilots. fuelPro has a dedicated interface in the platform just for pilots which we’ll look at in more detail further on. But first, some case studies.

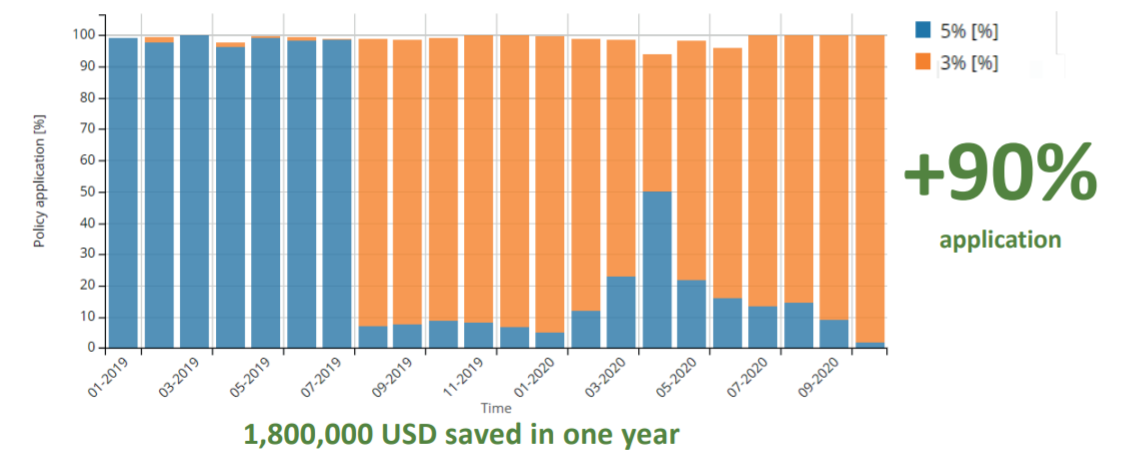

Case Study: Contingency Fuel

For the first case study, we’ll look at contingency fuel. Before even that, we need to clarify what is the purpose of contingency fuel. The basic definition states that contingency fuel is loaded to cover variations between planned and actual trip fuel for unexpected factors such as deviation from forecast weather conditions or the planned route. In general, it’s for deviations between planned and actual demand in favor. There are several methods for calculating contingency fuel. The basic ones are 5% of trip fuel, 3% of trip fuel or minimum contingency, reduced contingency fuel, and statistical contingency fuel.

As the chart shows (Figure 8), in LOT before the implementation of fuelPro, for long-haul flights contingency fuel was planned as 5% of trip fuel. Because there was not any proper software available with good quality data to check, the airline wasn’t fully aware of the situation or the saving potential. After implementing fuelPro, LOT was able to change policy and start planning contingency fuel as 3% of trip fuel. As you can see on the chart, that change is pretty visible. One year after commencing the application, LOT was able to save nearly 2 million dollars on this one initiative. But, implementing 3% contingency fuel is not the end of the story.LOT’s next step is to implement statistical contingency fuel and with fuelPro, it will be possible to succeed and save even more.

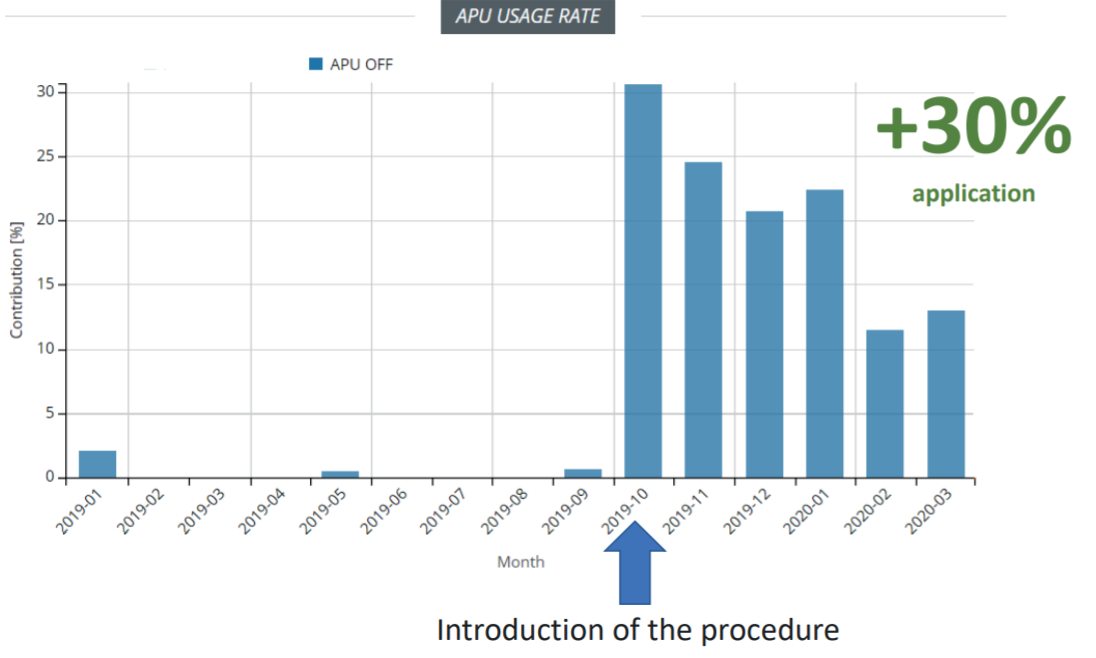

Case Study: APU Usage

Another case study from the LOT experience is how they managed APU (Auxiliary Power Unit) usage on the Boeing 787 and how fuelPro helped with that (Figure 9).

At LOT, a considerable effort is made in reducing fuel consumption and in-flight CO2 emissions on long-haul flights. However, once the aircraft lands, all of those benefits and savings can get thrown out of the window with inefficient ground operations procedures. APU is a great example. The airline knows that limiting APU usage ensures very significant savings in terms of fuel consumption and maintenance. Unfortunately, LOT’s resources weren’t enough to analyze FDR (Flight Data Recorder) data in terms of the APU. For proper monitoring, LOT wanted to have that data properly imported with software that will allow them to analyze APU usage based on multiple conditions such as aircraft type, airport, or weather conditions. None of that was possible before the implementation of FuelPro. Now, LOT analyzes APU usage for each phase in detail: taxi out, in-flight, taxi in, and turnaround. LOT started with APU usage at a taxi in phase in the home base, Warsaw Frederic Chopin Airport. 99 percent of taxiing phases at Warsaw were performed with the APU turned on. What is more, in some cases APU was turned on while the aircraft was still in the air, or even when electrically powered ground equipment was available after landing. Using FuelPro, LOT could share these results with the pilots to start a discussion about what changes could be made. As a result, an appropriate procedure has been introduced both for pilots and ground handling. Now, by using FuelPro, it is possible to check the application of APU fuel consumption usage and APU usage time. More importantly, LOT’s pilots can check their compliance with the procedure. On reducing APU usage during the taxi-in phase, LOT was able to save 35 kilograms of fuel for every 787 landing at Warsaw.

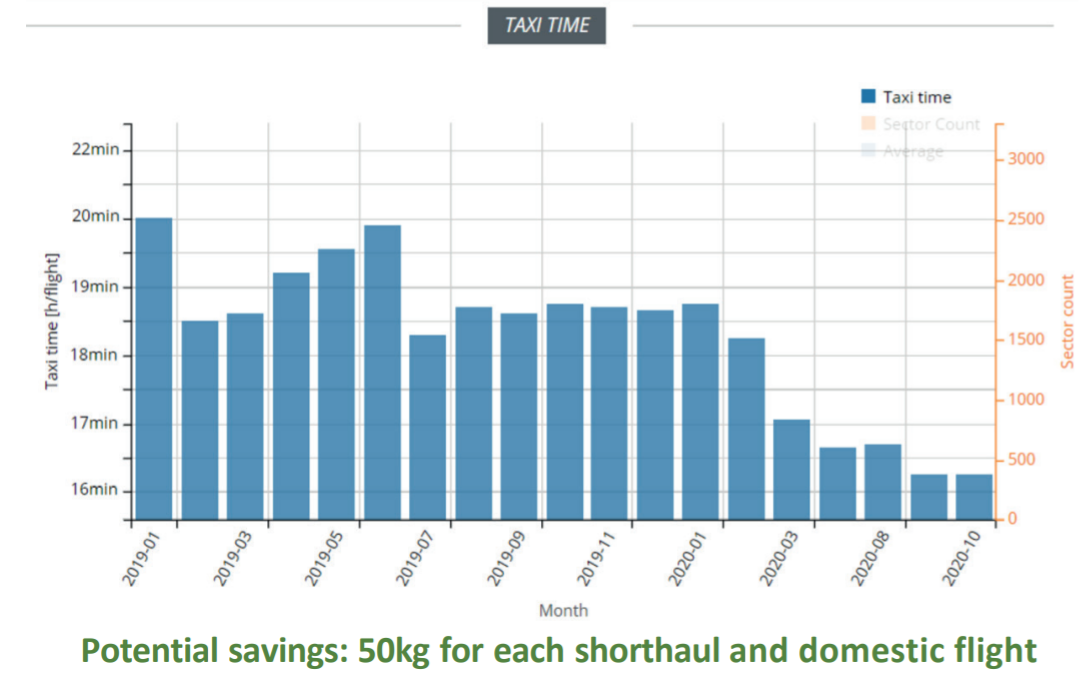

Case Study: Taxi Fuel Planning

This last case study is a great example of how fuelPro helped a LOT in dealing with an unexpected change in the aviation world. LOT planned a fixed amount of taxi fuel for every aircraft type having in mind that it might not be the most fuel-efficient way of doing it. However, as in the previous case, the airline did not have the software that would allow it to analyze and monitor the application of the changes. That is why LOT remained with the functioning way of taxi fuel planning. Even after the implementation of fuelPro, LOT did not change that policy. Knowing that it might be time-consuming and that savings might not be significant, it was left on the 'to do’ list while the airline focused on the initiatives with higher savings potential… then Covid happened.

Travel restrictions and flight reductions led to a decrease in airport traffic; less traffic meant shorter taxi times (figure 10) and shorter taxi times equal lower fuel consumption.

In FuelPro, new data from the flight data recorders are implemented into the platform every week. This way LOT was immediately able to notice a reduction in taxi time which correlated with a reduction in fuel consumption. Using fuelPro custom reports, LOT was able to track the data flight by flight and compare taxi fuel consumption before and during Covid, validated by aircraft type, departure airport, sectors, time of the day, delays, runways, and weather conditions. It seems like a lot of work but, in fact, the software did most of it. As a result, LOT was able to establish new taxi fuel values, not only for every aircraft type but also distinguished by departure airports. What is more, LOT can set targets for every airport and check the application of this policy.

At the time of writing, the implementation of this new policy was not complete but it was in its final phase. However, we hope that by sharing it we can show how fuelPro helped LOT to react in time and implement changes as soon as possible. With this new approach, LOT hopes to save up to 50kg of fuel for each short-haul and domestic flight.

Pilot’s Performance

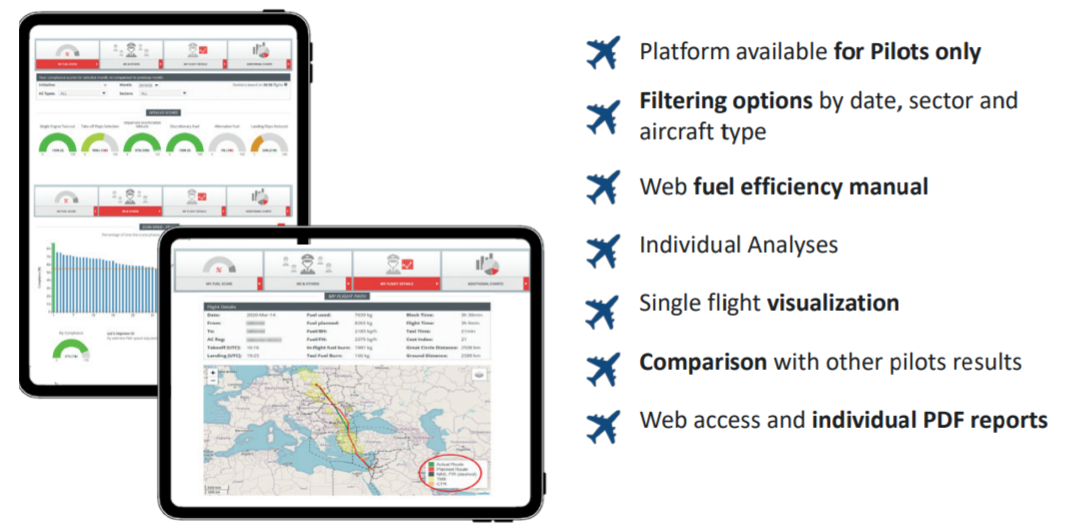

As we have already said, pilots are the key players in a successful fuel efficiency program. Because of that, LOT wanted to give them a tool with which they could check their achievements and see any remaining savings potential (Figure 11).

With the implementation of FuelPro, LOT’s pilots have a dedicated platform available for their eyes only. Each pilot can check details about their operations and compliance with cost-saving fuel initiatives in all flight stages. They can discover how successfully they used the established fuel policy in a particular month and can compare their performance with other pilots. They can also check one of their recent flights to see the route on the map and display the flight details. Additionally, extra charts can be created and made available for pilots on the platform. What is more, every pilot can check their performance for a chosen sector and aircraft type which, considering LOT’s fleet diversity, is a great feature. StorkJet also provides an online fuel efficiency manual to explain how the platform works and how to navigate it. Additionally, it provides an explanation of each fuel initiative and shares hints on how to improve. This is a great help for LOT because most of the questions that pilots might have been able to be answered immediately with a simple 'click’.

Especially for pilots’ performance, LOT needed the highest data quality and coverage possible to be sure that every piece of information shared with crews is correct. Once again, StorkJet met LOT’s expectations. As well as the web platform, LOT also wanted to share monthly fuel statistics with pilots via email. StorkJet was able to meet that need with the capability to create and share such reports, and they took responsibility for the distribution of those reports. While implementing this part of the system, LOT wanted to work in tight cooperation with the crews to meet their needs and create a tool that they would want to use.

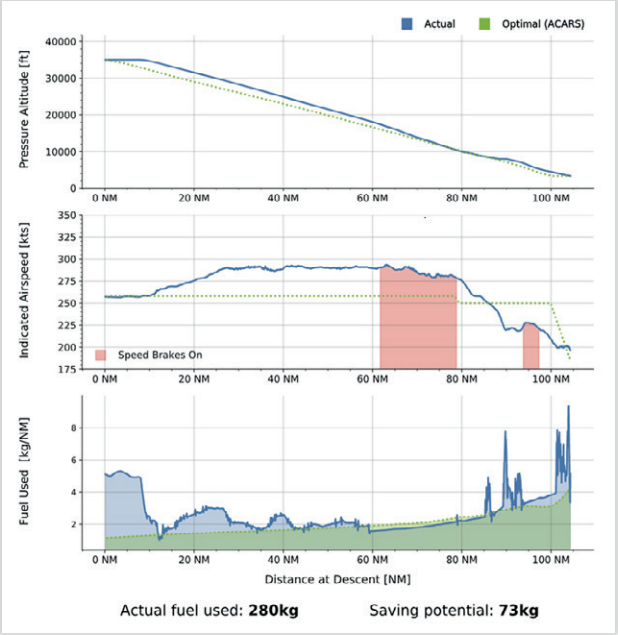

Different fleets had different requirements but, like every part of FuelPro, the Pilot’s Performance Tab is also customizable. Thanks to that, LOT was able to adjust expectations for both the short- and long-haul fleets. For each flight, pilots receive a comparison of the flight path with the most optimum one, calculated based on StorkJet’s tail-specific performance models with artificial intelligence (AI) applied. By comparing the most optimum flight path with the actual one flown, pilots can check what are the areas for improvement and what is the saving potential in every minute of the flight. Such charts are available for the climb, cruise, and descent phases. In Figure 12, you will see the descent chart with the actual flight path marked in blue and the optimal path marked in green.

- Optimum vs real flight path

- For the climb, cruise and descend

- Precise saving potential in every minute of the flight

- Calculations are based on QAR data and include gross weight, the deterioration of a specific tail, and the weather conditions

The first chart represents pressure altitude, the second chart indicated airspeed and the third one shows fuel usage. By analyzing such charts, pilots could see that the 'top of descent’ started too late. As a consequence, the aircraft was flying too fast and, in the end, the pilot had to apply the speed brakes to reach the appropriate speed. The fuel-saving potential calculated by StorkJet’s performance models is 73kg.

Every opinion about FuelPro that pilots share with LOT is positive: that means they are willing to use the solution and change their performance to more fuel-efficient and eco-friendly actions. So, it’s safe to say that both from an analytical and a pilot’s point of view, LOT can highly recommend this solution.

Final Thoughts

For LOT Polish Airlines, the StorkJet fuel efficiency software has been an eye-opener. Now the airline is able to track fuel efficiency initiatives and develop totally new ones. fuelPro is a powerful analysis tool that collects all fuel data from various sources into one application. It has enabled LOT to discover new fuel-saving possibilities and successfully implement them. By sharing the information with pilots, LOT is encouraging them to fly more efficiently and greener. They are much more aware of their fuel performance and ways to improve. And this is just the beginning!

Kamila Giżyńska joined LOT Polish Airlines in 2017. She takes care of introducing fuel efficiency initiatives and preparing analyzes which are the core elements of the Fuel Efficiency Committee work. Since 2019 she has been responsible for the implementation of the new operational efficiency software.

Kamila Giżyńska joined LOT Polish Airlines in 2017. She takes care of introducing fuel efficiency initiatives and preparing analyzes which are the core elements of the Fuel Efficiency Committee work. Since 2019 she has been responsible for the implementation of the new operational efficiency software.

Mateusz Dziudziel has been connected with LOT Polish Airlines since 2016. As Head of the Fuel Department, he is responsible for the management of fuel efficiency at LOT. Since 2017 he has been the Vice-Chairman of the Fuel Committee.

Mateusz Dziudziel has been connected with LOT Polish Airlines since 2016. As Head of the Fuel Department, he is responsible for the management of fuel efficiency at LOT. Since 2017 he has been the Vice-Chairman of the Fuel Committee.

LOT Polish Airlines is one of the twelve longest-established airlines in the world, with more than ninety-one years of operations. The flight network covers Europe, Asia, and, North America and is served by almost ninety aircraft, including jets and turboprops, from Embraer, Boeing, and Bombardier. The fleet is one of the youngest and most modern in Europe. One of LOT’s long-term goals is to operate more sustainably and reduce aviation’s CO2 footprint.

LOT Polish Airlines is one of the twelve longest-established airlines in the world, with more than ninety-one years of operations. The flight network covers Europe, Asia, and, North America and is served by almost ninety aircraft, including jets and turboprops, from Embraer, Boeing, and Bombardier. The fleet is one of the youngest and most modern in Europe. One of LOT’s long-term goals is to operate more sustainably and reduce aviation’s CO2 footprint.